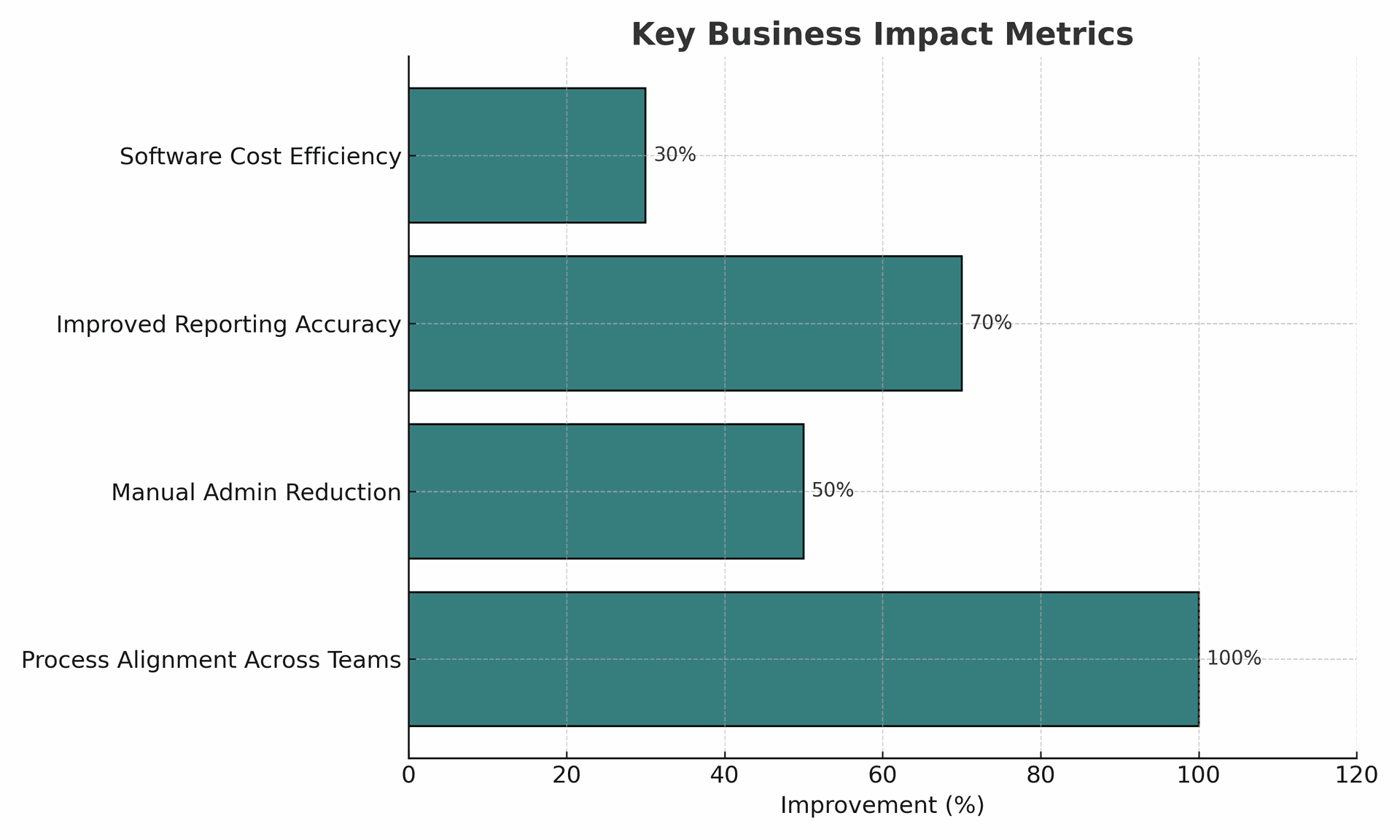

What they needed

Having the right tools isn’t enough. This business needed alignment across teams and systems to unlock real efficiency. We helped them reconnect their operations, reduce waste, and get more out of the tools they were already paying for.

Introduction

The tools were there, but the structure wasn’t. This company had invested in software but was using only a fraction of its potential. Key departments like Sales, Finance, and Delivery operated in silos, with data scattered across manual processes, emails, and even a single local computer. There was no clear view of performance, or how to improve it.

Image: Example of a company setup in Odoo

Challenge:

The business faced several operational gaps:

- Underutilised software, paying for licenses without results

- Sales, support, delivery, and finance workflows disconnected

- Manual tasks still handled by email or in person

- Data stored locally, not accessible across teams

- No insight into stock levels from maintenance reports

- Poor internal alignment made it hard to move forward

These gaps not only created inefficiency, they made it impossible to make informed decisions or scale sustainably.